Every secondary packaging operation is different. Each finds success with different methods of flow, and no two operations utilize the same methods, organization, or output levels. This makes it difficult to make a “one size fits all” plan for warehouses, distribution centers, manufacturing plants, and other similar facilities. Something all these facilities do have in common, however, is a drive to work continuously toward being more efficient and, thus, more profitable. Any and all ways to streamline secondary packaging are welcomed with open arms in any facility. Many operations turn to palletizer machines to help increase productivity.

A palletizer machine can do wonders for any secondary packaging operation. They work by unitizing your product load for added protection, efficiency, and automation. Each palletizer machine offers different benefits. Read below to investigate what to consider before purchasing a palletizer machine.

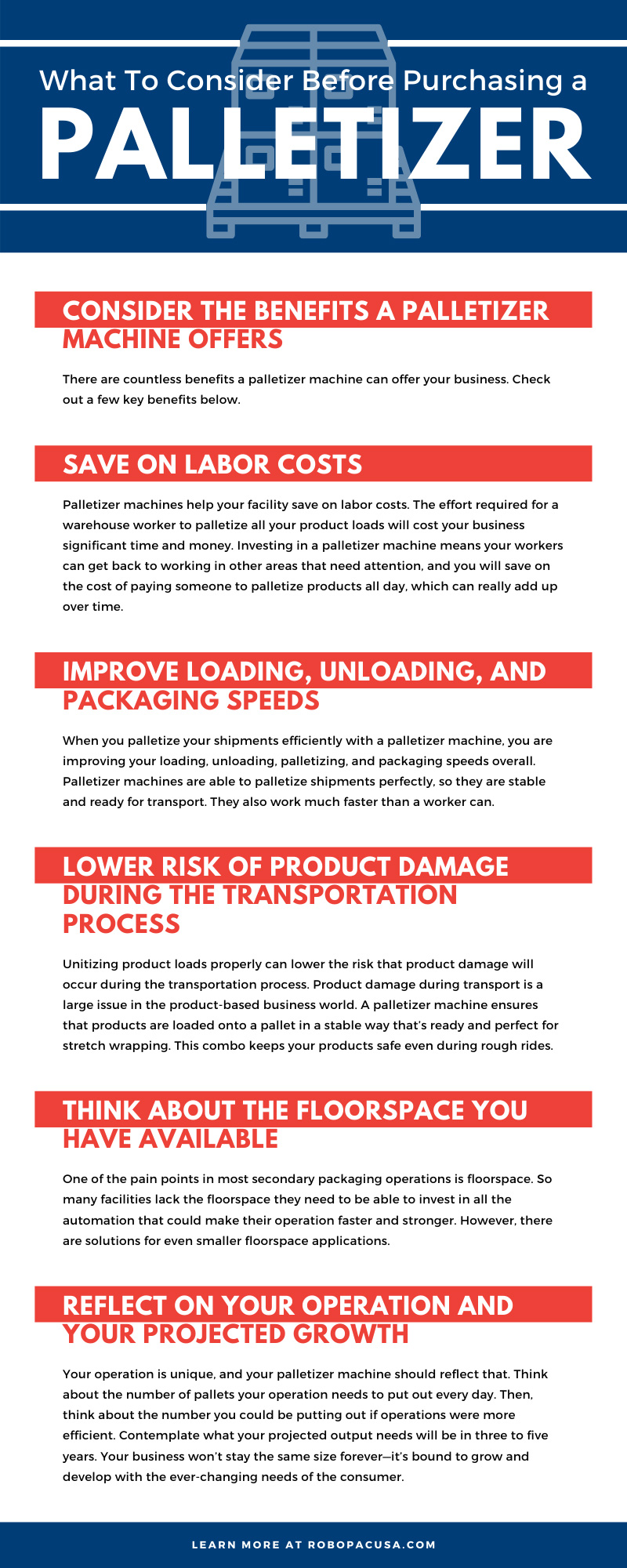

Consider the Benefits a Palletizer Machine Offers

There are countless benefits a palletizer machine can offer your business. Check out a few key benefits below.

Save on Labor Costs

Palletizer machines help your facility save on labor costs. The effort required for a warehouse worker to palletize all your product loads will cost your business significant time and money. Investing in a palletizer machine means your workers can get back to working in other areas that need attention, and you will save on the cost of paying someone to palletize products, which can really add up over time.

Improve Loading, Unloading, and Packaging Speeds

When you palletize your shipments efficiently with a palletizer machine, you are improving your loading, unloading, palletizing, and packaging speeds overall. Palletizer machines are able to palletize shipments perfectly, so they are stable and ready to be stretch wrapped on a pallet for transport. They also work much faster than a worker can.

Lower Risk of Product Damage During the Transportation Process

Unitizing product loads properly will lower the risk that primary packaging and product damage will occur during the transportation process. Product damage during transport is a large issue in the product-based business world. A palletizer machine ensures that products are loaded onto a pallet in a stable way that’s ready and perfect for stretch wrapping. This combo keeps your products safe even during rough rides.

Think About the Floorspace You Have Available

One of the pain points in most secondary packaging operations is floorspace. So many facilities lack the floorspace they need to be able to invest in all the automation that could make their operation faster and stronger. However, there are solutions for even smaller floorspace applications.

If your operation doesn’t have the floor space for all the equipment that can help your company exceed expectations, consider a manufacturer that makes a concurrent stretch wrapper and palletizer machine. This type of two-in-one machine cuts down on the amount of space required to make automation possible in your facility. Plus, purchasing a palletizer with a built-in stretch wrapper will reduce your overall automation investment costs.

Reflect on Your Operation and Your Projected Growth

Your operation is unique, and your palletizer machine should reflect that. Think about the number of pallets your operation needs to put out every day. Then, think about the number you could be putting out if operations were more efficient. Contemplate what your projected output needs will be in three to five years. Your business won’t stay the same size forever—it’s bound to grow and develop with the ever-changing needs of the consumer. Reassess your company’s projected growth and invest in a machine that can work for your current and future packaging needs.

Contemplate the Quality of the Manufacturer

Many facility managers and owners forget to consider the key role a machine manufacturer plays in the quality of a machine and its ease of use. Once you purchase a machine, the manufacturing company could easily abandon you to figure things out on your own. You want to choose a company that will act as your partner and will care deeply about the success of your operation and the role their machine plays in it.

Robopac USA cares about our customers. We build our machines with superior technology to help your operation run smoothly. Our team is easy to contact and is excited about the opportunity to help your operation grow and develop in this age of automation.

Explore the Different Options of Palletizers

There are many different types of palletizers you should consider before purchasing. Understanding all your options is vital to making the right decision. Not every palletizer is right for every operation, so it’s essential that you understand the unique benefits each offers to find which option fits best with your specific secondary packaging operation. Below are the various types of palletizer machines that Robopac USA offers.

- Pick N Place Robotic

- Low Infeed Conventional

- High Infeed Conventional

Many of our machines have a modular design for top quality control and complete layout flexibility—no customization required. Discover which option is right for you by contacting our team today!

Do What’s Right for Your Facility

At the end of the day, you know your facility better than anyone. You know what floor space is available, how much you currently output, how much you are projected to output in the next few years. You are the expert in your facility, and a palletizer machine should work to make your life and the lives of your workers easier.

If you are thinking about investing in a palletizer machine, do your facility a favor and partner with a manufacturer you trust. Invest in a palletizer machine that will work for you and keep up with the demands of your operation.

Robopac USA manufactures top-quality palletizer machines that are designed to make your operation more efficient, more productive, safer, faster, and more profitable. Purchasing a Robopac USA palletizer machine is a great investment for your business. There are endless benefits a palletizer can bring to your secondary packaging operation. Be sure to examine and explore what to consider before purchasing a palletizer machine. Contact Robopac USA today for more information and for help finding the perfect machine for your operation.