Automated guided vehicles (AGVs) are a great way to increase efficiency, safety, and productivity in your facility. Like all equipment, though, AGVs require expert installation and integration to bring success to your business. By creating a thorough implementation plan, you can create a smooth transition and make the most of your new equipment. Learn more with these tips for implementing AGVs in your facility.

Create Proper Navigation Lanes

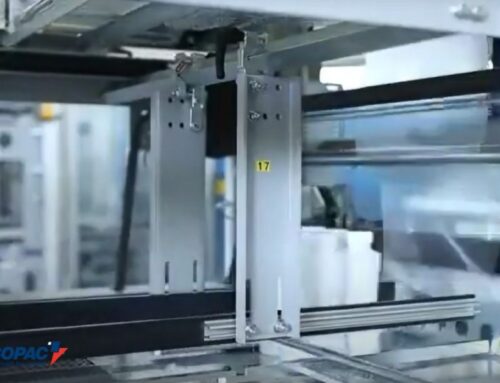

Laser-guided vehicles and other types of AGVs require specific floor plans to function safely and effectively. Depending on your current facility layout, you might need to make significant changes to your floor plan to create routes that AGVs can navigate.

Take extra care if you also use forklifts or other material handling equipment. Keep forklift routes and AGV routes separate to avoid traffic jams or collisions.

Know Your Vehicle Needs and Limitations

Every AGV system is different. Before you implement your AGVs, you need to consider the system’s needs and limitations. How fast can the vehicles move through your warehouse, and what do you need to do to accommodate that speed? Can the vehicles drive in reverse? Do they need rear-facing sensors?

Asking these questions will help you understand exactly how your AGV system is able to interact with your facility layout. With this information, you can make a plan and upgrade your space to take full advantage of your AGVs.

Choose the Right Supplier

AGV systems help businesses reduce operator costs and time spent on non-value-added tasks. This leads to increased cost savings in the long run, but that doesn’t change the fact that AGVs are initially a significant investment. As you plan for and choose your AGV system, make sure you’re getting your money’s worth by choosing a reliable supplier.

Working with an expert supplier is one of the most important tips for implementing AGVs in your facility. A knowledgeable vendor like Robopac USA will help you find the best system for your facility and workflow. The right supplier will also provide value-added services such as training and ongoing support. In addition to making a smoother initial transition, these supportive services help you minimize equipment downtime and continue making the most of your AGVs in the years to come.

Improve efficiency and productivity in your facility when you contact Robopac USA. We’ll help you find the perfect laser-guided vehicle system for your needs so that you can make the most of your equipment.