Stretch wrapping machines play an integral role in a business’s end of line packaging operation. These devices, designed to protect your products quickly and thoroughly for the distribution process, help your products reach their destination in the same condition they left. They also allow you to maximize the efficiency of your operations by reducing the amount of work needed by hand. This allows you to reallocate the labor to different tasks or reduce labor costs if necessary.

Semi-automatic stretch wrappers are especially popular for their ability to accurately wrap even varying types of packages. Though, in some cases, they still require some human involvement, such as attaching film and pressing the start button, they are still an incredibly beneficial tool to have at your disposal. However, it is important to note that there is more than one model of semi-automatic stretch wrappers, and the type you choose can impact its success when working with your particular products. These are the different semi-automatic stretch wrappers and their advantages.

The Types of Semi-Automatic Stretch Wrappers

As alluded to previously, the key to achieving the optimal balance between your secondary packaging’s quality and operational efficiency lies with the equipment you choose. From turntable models to rotary arm and portable varieties, there are ample semi-automatic stretch wrappers for you to pick from. As such, it’s vital that you understand each of their distinct capabilities before you decide which is best for your needs. These are the primary types of semi-automatic stretch wrappers for you to keep in mind.

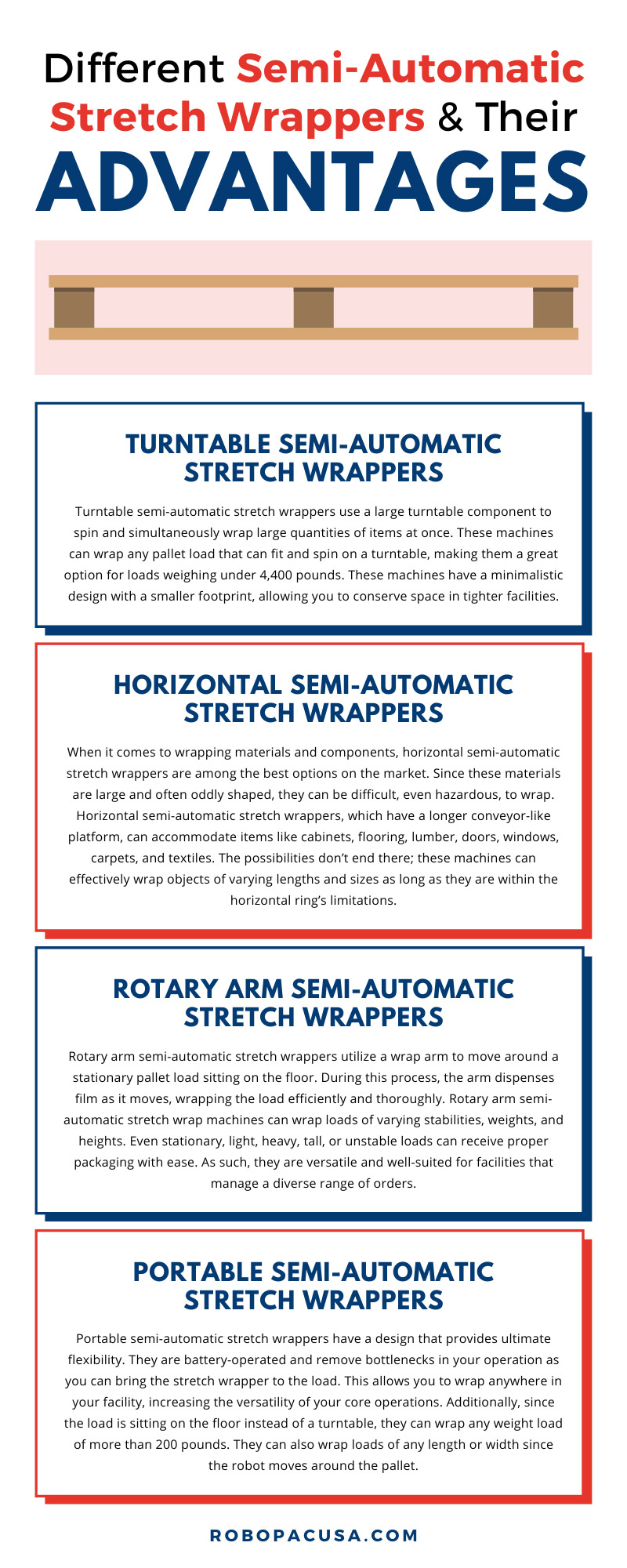

Turntable Semi-Automatic Stretch Wrappers

As their name suggests, turntable semi-automatic stretch wrappers use a large turntable component to spin and simultaneously wrap large quantities of items at once. These machines can wrap any pallet load that can fit and spin on a turntable, making them a great option for loads weighing under 4,400 pounds. These machines have a minimalistic design with a smaller footprint, allowing you to conserve space in tighter facilities. They are also available in two different wrap heights: 86” or 110”. This way, you have additional options for packaging loads of different dimensions.

Horizontal Semi-Automatic Stretch Wrappers

When it comes to wrapping materials and components, horizontal semi-automatic stretch wrappers are among the best options on the market. Since these materials are large and often oddly shaped, they can be difficult, even hazardous, to wrap. Horizontal semi-automatic stretch wrappers, which have a longer conveyor-like platform, can accommodate items like cabinets, flooring, lumber, doors, windows, carpets, and textiles. The possibilities don’t end there; these machines can effectively wrap objects of varying lengths and sizes as long as they are within the horizontal ring’s limitations.

Rotary Arm Semi-Automatic Stretch Wrappers

Rotary arm semi-automatic stretch wrappers utilize a wrap arm to move around a stationary pallet load sitting on the floor. During this process, the arm dispenses film as it moves, wrapping the load efficiently and thoroughly. Rotary arm semi-automatic stretch wrap machines can wrap loads of varying stabilities, weights, and heights. Even stationary, light, heavy, tall, or unstable loads can receive proper packaging with ease. As such, they are versatile and well-suited for facilities that manage a diverse range of orders.

Portable Semi-Automatic Stretch Wrappers

Portable semi-automatic stretch wrappers have a design that provides ultimate flexibility. They are battery-operated and remove bottlenecks in your operation as you can bring the stretch wrapper to the load. This allows you to wrap anywhere in your facility, increasing the versatility of your core operations. Additionally, since the load is sitting on the floor instead of a turntable, they can wrap any weight load of more than 200 pounds. They can also wrap loads of any length or width since the robot moves around the pallet.

Additional Semi-Automatic Stretch Wrapper Features

Even after discussing the different semi-automatic stretch wrappers and their advantages, there is still a lot more to learn. In fact, there are a series of additional semi-automatic stretch wrapper features to consider as you decide which one is right for you. These options provide other secondary packaging capabilities to improve the diversity of machine applications. Here are a few features and options to note.

Roping Devices

Roping devices, for starters, allow you to reduce the width of the film into a rope or cable. When wrapped around a load, this provides it with better protection and keeps the items more stabilized and secured to the pallet. This process also helps reduce the occurrence of condensation on certain types of loads, preserving the products during transport. Robopac USA offers both automatic variable roping and pneumatic roping devices for you to browse.

Weighing System Kits

Including a weighing system under your semi-automatic turntable stretch wrapping machine allows you to weigh each load without needing to transport it to a separate area of your facility. These devices make the wrapping and weighing process simultaneous, shaving minutes from the processing of each parcel and allowing you to devote that time to other operations. This feature also helps reduce the risk of overpaying for re-weigh fees by increasing accuracy and cutting down on the amount of labor wasted in your warehouse. Remember, though, that weighing systems work on turntable semi-automatic stretch wrappers only.

Ramps

Ramps also work on turntable models only, though they are just as helpful. Lifting heavy loads onto the turntable can be a challenge, but these features allow for easy access with a pallet jack. Robopac USA offers several different ramps to suit your distinct loading needs, making it simpler to find something that accommodates your operations. These products are durable, making them capable of withstanding substantial quantities of weight. They are also quick to install and take up a small amount of floor space for optimal floor conservation. This way, you can reap the benefits without obstructing the traffic flow of your facility.

If you need a premium semi-automatic stretch wrap machine for your secondary packaging facility, Robopac USA has a diverse selection for you to pick from. We carry a series of different models, including the ones listed previously, to best accommodate your business’s specific needs. We work hard to create products that ensure your operations are efficient and practical. So you will never need to worry about quality secondary packaging again when you shop with us. Contact Robopac USA today to learn more about how we can improve your warehouse’s performance.