So much of your business revolves around a successful packaging and shipping process. If you cut corners with your packaging solution—through poor quality materials, unorganized processes, or slow and unreliable shipping methods—then you will face product loss, frustrated customers, and poor sales. At the same time, spending too much time and money on your packaging process can turn into a costly endeavor that strains your budget and hinders your growth.

Implementing and maintaining a cost-effective packaging line means learning how to balance efficiency with quality to create the most dependable and lasting solutions possible. See how you can improve your bottom line while still delivering quality products to your customers with these ways your business can save money on packaging costs.

Invest in Durable Packaging

It can be tempting to save money by using cheaper materials that help you streamline your packaging process. Unfortunately, cheaper, lower-quality materials don’t offer suitable protection for your products. This means you’ll face even greater expenses because of product damage, poor customer reviews, and lost sales. High-quality packaging materials are an investment that will pay off in the long run.

This doesn’t mean you should splurge on the heaviest, sturdiest packaging materials out there, though. Instead, choose options that balance durability with a lightweight, sustainable design. Remember that packaging isn’t a one-size-fits-all solution. Use different packaging types to best protect the various products you sell. You can deliver products in pristine condition while also minimizing waste by choosing packaging that fits each specific product.

Create an Efficient Warehouse Design

Using your floor space wisely helps you move products through your packaging line much faster. For example, a packaging line that crosses over itself or takes the product across the entire facility means longer transit times, more traffic jams within your facility, and other complications. Avoid these issues by implementing strategic layouts that allow for smooth and efficient movement of goods throughout your operations.

It also helps to combine multiple steps in your workflow with advanced packaging equipment. Turntables that have built-in pallet scales and palletizers with concurrent stretch wrapping help consolidate different stages of your packaging line. This creates a more streamlined process that moves goods through your facility in less time without sacrificing quality.

Enhance Inventory and Material Storage

A well-organized storage system and automated inventory tracking help ensure you know where everything is in your facility at all times. Poor organization can lead to workers wasting time trying to find misplaced materials. Even worse, inefficient inventory management can result in missing products or materials, which slows down or outright halts your packaging line.

Enhancing your facility’s inventory through solutions like warehouse management systems helps minimize these issues. Tools such as inventory tracking, automated storage and retrieval systems, sales analysis and predictions, and automatic ordering all help ensure a smooth workflow with minimal disruptions.

Keep Improving Packaging Design

The packaging industry is in constant motion. There are always new solutions and innovations changing the game. If you want to stay ahead, you need to be able to adapt alongside the rest of the industry. This means continuously improving your packaging design to deliver optimal solutions for your customers.

Optimizing your packaging design might take some trial and error. This is an investment of both time and money, but it pays off when you create and implement dependable, efficient, and cost-effective packaging solutions. By staying flexible and innovative, you can continue offering modern solutions that meet the demands of your customers and set your business apart from competitors.

Maintain a Proactive Warehouse

If you wait until something goes wrong before you change your processes, then you’re already starting on the back foot. This means you’ve already experienced increased costs, significant downtime, or other issues. However, if you make proactive changes in your packaging line, you can continuously improve your processes and avoid these problems altogether.

It’s never a bad idea to plan ahead. When you’re always on the lookout for new ways to save money or boost efficiency, you can overcome challenges before they arise. Being proactive can include everything from performing preventative maintenance on your equipment to using predictive analytics to stay on top of industry trends. By paying attention to what’s happening within and beyond your facility, you can make informed, strategic decisions that bring the most value to your business.

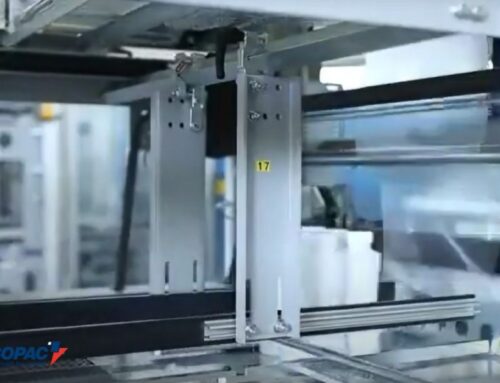

Invest in Packing Automation

One of the most effective ways for businesses to save money on packaging costs is to invest in automated packing solutions like case packers. Manual case packing takes an extreme amount of time and money. Automation, on the other hand, helps lower costs through increased consistency, faster packing speeds, enhanced flexibility, and greater safety for both products and employees.

To make the most of your automation, you need to invest in the right equipment solutions. Case packer wrap around machines are among the most cost-effective upgrades for your packaging line. In addition to a wrap around case packing format, in some cases, these machines can also pack in other formats. Below are just a few of the ways wrap around case packers can help optimize your workflow.

Consistency and Efficiency

Like all automated packaging solutions, case packers deliver better speed and precision than their manual alternatives. Manual labor inevitably leads to human error, but automatic case packers ensure that products undergo precise and accurate packing every single time. Case packers also move much faster than even the best employees can manage. This allows you to move more products through your packaging line in less time than ever before. You save time and money while experiencing a fast return on investment for your machine.

Enhanced Flexibility

Flexibility is another benefit of automatic case packers. Multi-format case packers have easy, stress-free changeover processes that allow you to move different products through the same packaging line with minimal downtime. As a result, case packers offer a single solution for all your different product needs. This improves workflow efficiency and prevents you from spending excess money on multiple packing solutions.

Create a Cost-Effective Workflow With Robopac USA

The right equipment can help you increase efficiency, productivity, and cost-savings in your packaging line. Work with Robopac USA today to find optimized packaging equipment like our multi-format case packers. With advanced secondary packaging solutions, you can set your business up for greater success than ever before.