Businesses face many different challenges in their supply chains, but refrigerated products are among the most intimidating obstacles. In addition to ensuring a smooth production line, efficient shipment, and general product safety, you must also provide consistent temperatures, proper ventilation, and more to keep goods fresh and safe long enough to reach your customers.

Many best practices go into making sure food, beverages, pet food, and other refrigerated products reach their destination safely. Whether you’re selling refrigerated products for the first time or simply looking for ways to improve your processes, brush up on these expert tips for stretch-wrapping refrigerated products.

The Dangers of Improper Wrapping

Like with any product, refrigerated goods require proper wrapping techniques to ensure they arrive in pristine condition. However, there are specific dangers that come with improperly wrapping refrigerated goods. In addition to the risk of spills, crushed products, and other general damage, refrigerated goods can become bruised or spoiled if you don’t package them correctly. Even if you achieve proper temperature control with your wrapping process, you can experience excess moisture and condensation if you don’t provide correct ventilation. This, in turn, leads to dampness and mold.

Refrigerated products—especially food and beverage products—can create a lot of waste and profit loss if you’re not careful. But by paying close attention to temperature control, insulation, and packaging best practices, you can protect your refrigerated products and deliver the best quality goods to your customers.

Use Insulation Methods

When it comes to stretch-wrapping refrigerated products, insulation methods play a crucial role in maintaining the desired temperature, especially for highly temperature-sensitive products like meat, seafood, and dairy.

Specialized solutions with unique containers and cooling materials help keep a consistent temperature during transportation or storage. These solutions include insulated boxes, liners, ice packs, dry ice, gel packs, and more. Choosing the proper insulation method is essential based on the type of product you’re working with, your desired temperature range, how and where you’re shipping the product, and other shipping details. With proper insulation, businesses can ensure that their refrigerated products remain fresh and safe for consumption.

The Importance of Ventilation

In addition to establishing proper temperature control, you must think about ventilation. Stretch wrapping that allows for ventilation helps prevent condensation on cooler products, allowing fresh produce and other goods to breathe so that they don’t spoil as they move through your supply chain.

There are several tips for ventilating your pallet loads, many of which revolve around how you use your stretch film. Remember that tighter wraps that cover the entire load leave less room for breathability. Instead, consider using techniques such as stretch film roping to wrap the product without covering the whole pallet. Netted film is another option to allow the products to breathe. This helps your goods stay fresh and cool without the risk of excess condensation.

Be Smart About Film Tension

Film tension and containment force affect temperature control and ventilation. For refrigerated products, starting your wrapping process with less tension and slower wrap speeds is smart. This allows you to secure the product load without creating a containment force that is so strong that it prevents breathability. As you wrap, you can gradually increase the tension and wrap speeds to achieve an optimized containment force that will keep your load stable as it moves through the supply chain.

Avoid Corner Damage

Broken or torn stretch film is a problem no matter what types of products you’re working with. When it comes to refrigerated products, though, damaged stretch film poses the additional risk of ruining your temperature control, ventilation, and other crucial conditions protecting your goods.

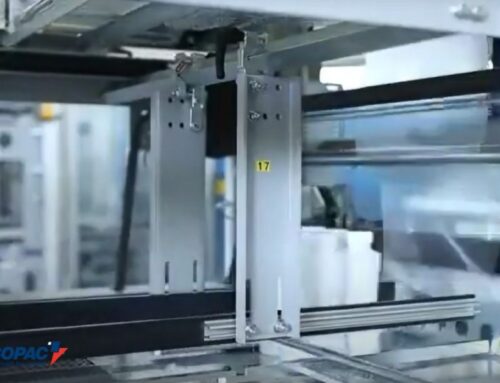

One of the best ways to avoid broken stretch film is to take care when wrapping the corners of your pallet—particularly if you’re wrapping products with sharp edges, such as crates of produce. Avoid corner damage by using superior stretch wrapping technology. Robopac’s Cube Technology includes proactive corner compensation, which reduces the likelihood of film breaks on sharp corners. You can also use protective corner boards to cover the sides of your pallet and prevent tears on those sharp corners.

Use Reinforcement Techniques

Reinforcement techniques are also essential when stretch-wrapping refrigerated products. One common solution is roping, which involves tying the load to the pallet to ensure it remains secure during transportation and storage. This technique ensures that the load does not shift or move, which can cause damage to the product and increase the risk of temperature fluctuations.

While reinforcing the load to the pallet is always a best practice, it becomes even more critical when temperature control is at stake. By using roping and other reinforcement techniques, businesses can mitigate the risk of damage to their refrigerated products and ensure they remain safe for consumption.

Efficiency Is Key

Working with refrigerated products also often means working with shorter expiration dates. As a result, efficiency is key when it comes to moving refrigerated products quickly and safely through the supply chain.

One way to improve efficiency is by using stretch film wrapping machines and other automated packaging equipment that can safely handle products and materials to create secure product loads in less time. Automated equipment significantly reduces the time required to package and transport products, leading to cost savings and improved overall efficiency. By focusing on efficiency and leveraging automated packaging equipment, businesses can optimize their supply chain and ensure that refrigerated products reach their destination quickly and safely.

Ensure Proper Storage

Proper packaging processes are essential, but they won’t be effective if the facility and storage areas don’t support refrigerated products. To ensure that products remain at the desired temperature during storage, it’s important to have a clear and accessible storage area that is temperature-controlled and well-ventilated. This will prevent issues such as excess moisture, condensation, and mold growth, which can lead to spoilage and significant financial losses.

It’s also necessary to ensure that other stages of the supply chain, including temperature-controlled trucks and other transportation methods, meet the same standards for temperature control. Businesses should regularly monitor and adjust their storage and transportation methods to ensure that refrigerated products remain at the desired temperature throughout the entire supply chain. By prioritizing proper storage and transportation methods, businesses can maintain the integrity of their refrigerated products and ensure customer satisfaction.

The right secondary packaging equipment can help you protect refrigerated goods and deliver high-quality products to your customers every time. Visit Robopac USA today to see how our machines can help optimize your packaging line.