By integrating semi-automatic machinery into your shipping processes, you not only showcase your brand’s dedication to efficiency and consistency but also the potential for further enhancements and opportunities. So why stop there?

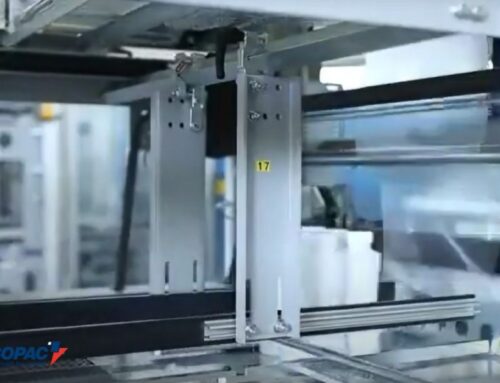

Continue maximizing your operational success with our weighing system kit which is uniquely designed for our semi-automatic turntable stretch wrappers. Rely on Robopac for the most innovative equipment in the secondary packaging industry and reap the benefits of this two-in-one system. A few of the advantages include:

- A streamlined workflow

With a weighing system kit installed into your turntable stretch wrapper, you eliminate the need for separate weighing processes after wrapping the load. Moreso, minimizing the double handling and time wasted moving the load to a separate scale.

Without a weighing system kit, the typical process consists of transferring a wrapped pallet to a separate scale, which can result in 30-90 seconds of double handling loads equally $7,000-15,000 in wasted labor over five years.

- Accuracy

Using an undermount weighing system kit eliminates potential errors when transferring the wrapped pallet to a separate scale. With the two-in-one system, you are guaranteed precise weight measurements each time. Thereby reducing the risk of shipment error and associated costs.

Regardless of whether you are using Robopac’s weighing system kit, measuring, and recording accurate pallet weight is a practice that must be implemented in every end-of-line process before shipment.

“Weighing your pallet loads is a massive asset because you know exactly how much you are shipping. You must know this because you can’t make decisions and save yourself money without it,” said Vicki Larson from LDS Logistics LLC.

Larson emphasized two reasons pallet weight is crucial: Reweigh Fees and Theft.

Re-Weigh Fees

The financial consequences of overlooking pallet weight can vary depending on company size, shipment volume, and weight discrepancies. Nevertheless, no one is free from reclassification and reweight fees during transportation and delivery.

According to Koho, an LTL freight and shipping platform, reclassification and reweigh fees are among the most common fees shippers will see:

“Delays that keep the driver waiting, inaccurate freight measurements or weights, incorrect paperwork, or unexpected equipment needed to load or unload your cargo can all result in unpleasant surprises on your invoice. And they can be substantial.”

Carriers will calculate freight charges based on the dimensions of each load and by having accurate documentation of pallet weight you can ensure that your company is appropriately billed. Further, allowing you to properly predict and allocate transportation expenses.

Even so, Robopac’s National Distribution Sales Manager David Brooks said he has taken notice of brands estimating their pallet weights, rather than affirming load accuracy on a scale. Estimating pallet weight raises several concerns, as it can put your brand at risk of overestimation or underestimation.

Overestimation can result in higher shipping costs than necessary, emanating decreased profitability. While underestimating can lead to the underpayment of shipping charges. If the carrier notices that the actual weight exceeds the estimated weight, the carrier could reweigh the shipment and charge you for the difference. Hence, having the proper weight beforehand can eliminate potential transportation pains and financial strain.

“If they overestimate the cost, the freight companies are going to charge more, and if they underestimate the weight, then the truck driver gets charged.

“The bill of lading tells you how much everything weighs, so if you have to stop at a scale on the highway and the weight was underestimated or overestimated, there’s going to be a problem,” said Brooks.

If the bill of lading and the actual weight don’t match the load is required to be reweighed, becoming a hassle for all involved. Larson elaborated on this process:

“Most carriers will charge you a reweight fee of anywhere from $25 to $55 just for taking it and having to reweigh it. It doesn’t matter if it only reweighed by three pounds; you just got hit with another $55 charge you hadn’t expected. If it changes class, it could even triple your cost,” said Larson.

Depending on the jurisdiction and severity of the violation, non-compliance with weight restrictions and regulations can even result in legal consequences. Moreover, repeat violations can lead to substantial financial and legal penalties.

Theft

In 2022 alone, CargoNet recorded 1,778 supply chain risks events across the United States and Canada, an increase of 15% from 2021.

“Supply chain disruptions were one of the main concerns of the year because of their effect on inflation…The average value of cargo stolen in an event was $214,104, and it is estimated that $223 million was stolen across all cargo theft events in 2022.”

No industry is safe from the looming threat of theft, yet the food and beverage industry has become the most targeted industry in the United States due to current economic conditions. As serial numbers make certain products nearly impossible to track, the food and beverage industry stands as an easy target for thieves.

Consumer electronics and pharmaceuticals also stand at high risk due to high consumer demand and high value for resale on the black market. Pharmaceuticals have become a largely attractive industry for thieves because of heightened prescription prices following the pandemic.

Properly weighing and recording pallet weight before shipment can act as a direct deterrent to theft. By committing to accurate documentation, companies may be viewed as less vulnerable targets to potential thieves. Accurate weight measurements can also be useful in the facilitation of insurance claims if theft does occur, as it assists in establishing the value of the stolen product.

“So many things get stolen…pills especially are a big deal. Only one bottle you’d think no one’s going to notice. Well, if you use a scale, you’d notice,” said Larson.

In the case of tampering or theft, having such information on hand can identify significant weight deviations between the expected and actual weights; this allows for early detection of anomalies, triggering additional security measures and investigations to prevent or address theft incidents.

Your brand demonstrates its commitment to efficiency, accuracy, and security by investing in Robopac’s weighing systems kit for your semi-automatic turntable stretch wrappers. Easily

mitigate transportation’s financial and security risks with accurate pallet weight and guarantee existing and potential customers that your brand is taking necessary precautions in the initial stages of the transaction.

Enhanced operational success awaits. For more information on our weighing system kit, click here.