It’s easy for warehouses to forget about product loads once they’re out the door and on their way through the supply chain. If you want your supply chain to be as successful as possible, though, you must pay close attention to product handling and safety every step of the way. Adopting cost-effective ways to avoid product damage when shipping domestically helps you deliver high-quality goods to end users with minimal waste, delays, and lost sales. Enhance your supply chain with these methods for securing products during transportation, storage, and more.

Balance Efficiency With Quality

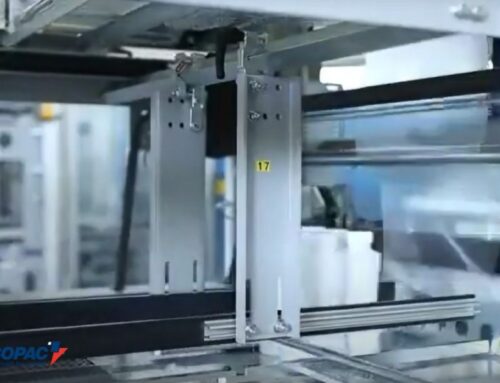

Fast shipping processes mean more sales. However, this can also mean cutting corners and following unsafe packaging practices. Don’t let the need for efficiency outweigh the need for quality. Take the time to load products safely, implement reliable wrapping processes, and perform quality control inspections every step of the way. Use solutions like automatic pallet wrapping turntables to speed up your workflow without sacrificing quality and reliability.

Run Product Load Tests

You can’t guarantee a smooth ride for your product loads. There are going to be bumps along the road—literally. That’s why impact tests or edge crush tests are an important part of avoiding product damage when shipping domestically. Impact or drop tests simulate the bumps, shifts, and other movement your products will face during transit, while edge crush tests determine how much weight a case or product load can support before it collapses. Robopac’s TechLab provides you with the opportunity to receive comprehensive scientific testing. You’ll work with our sales team to schedule testing at our Duluth Georgia facility. With these tests, you will receive data showing you potential cost savings, damage reduction, and sustainability improvements.

These practices help set safe standards for creating pallet loads. With this information, you can assemble efficient and secure loads that are sturdy enough to make it through storage and transportation without damage.

Wrap With the Proper Containment Force

One of the most important aspects of proper wrapping is containment force. Robopac USA’s automatic and semi-automatic stretch wrappers create precise containment force with our exclusive Cube Technology. By dividing the product load into 9 or 12 programmable layers and offering complete control of unit speed, film carriage speed, pre-stretch, wrapping force, and more, Cube Technology delivers ultimate stability and efficiency within your packaging line.

Don’t let product damage create unnecessary expenses for your domestic supply chain. Partner with Robopac USA to implement your optimized secondary packaging solution today.