In today’s business world, it is more important than ever to find ways to increase efficiency and optimize production. One way to achieve this is through the use of an end-of-line automation system. This system can automate a wide variety of tasks that are typically done by hand, such as packaging, labeling, and sorting. As a result, businesses can see significant increases in productivity and reductions in labor costs. Read on to learn more about the benefits of an end-of-line automation system and explore the types of automation that can benefit your facility.

What Is an End-of-Line Automation System?

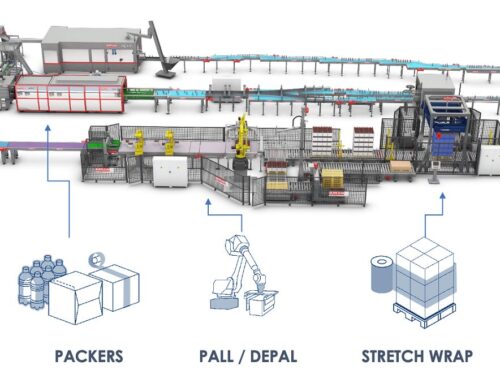

Most warehouses and distribution centers use an automated system to move inventory from one location to another. This type of system is called an end-of-line automation system, and it can be used for a variety of tasks, including picking, packing, and sorting. In addition to increasing efficiency, end-of-line automation systems can also help to improve accuracy and reduce costs.

For example, an automated case packer is a robust, high-tech machine that packs your products into a variety of formats: film only, pad and film, tray and film, or wrap-around cases. Wrap-around machines allow you to efficiently pack a wide range of products with minimal changeover times to meet speed and flexibility requirements. This is just one example of how automating the tasks of picking, packing, and sorting can improve your business’ bottom line.

Benefits of Using End-of-Line Automation

End-of-line automation systems offer several benefits for businesses that implement them. Perhaps most importantly, end-of-line automation can significantly improve efficiency and productivity. By automating tasks that are typically performed manually, businesses can free up employees to focus on more value-added activities.

In addition, end-of-line automation can help to improve product quality by reducing the opportunity for human error. Moreover, end-of-line automation systems can help to improve safety in the workplace by eliminating potential hazards associated with manual tasks.

Choosing the Right End-of-Line Automation System

When it comes to end-of-line automation, there are a few things you need to take into account in order to choose the right system for your business. The type of products you produce, the number of products you produce, and the budget you have for automation are all important factors to consider.

Ultimately, the best way to reap the benefits of an end-of-line automation system is to consult with an experienced provider who can help you assess your specific needs and find a solution that fits both your products and your budget. Contact the team at Robopac USA to explore case packers and other secondary packaging solutions to optimize your facility’s end-of-line automation system.