Most business owners know that when it comes to shipping products, weight is a major concern; in most cases, the more something weighs, the more it costs to ship. Therefore, many business owners choose to weigh their pallets before shipping them. See how a stretch wrapper with a weighing system saves your business money while streamlining operations with these reasons to weigh your pallets for shipping.

Control Shipping Costs

Any business that ships products must be aware of the costs associated with shipping. Shipping costs can add up, and it’s important to make sure you’re not being overcharged. Weighing your loads gives you the confidence that they were processed accurately. This way, you can be sure that shipping companies are not rounding up or inaccurately recording the weight.

Another reason to weigh your pallets for shipping is that doing so can help you avoid overloading your trucks, which can result in costly fines. Taking a few minutes to weigh your shipments can save you a lot of money in the long run.

Monitor Theft

Weighing your pallets before shipment also helps you identify and address theft in your supply chain. If the weight changes at any point during transit, it can indicate that something has been removed from the shipment. By keeping track of the weight, you can ensure that all your products arrive at their destinations safely and as intended. With a little careful planning, you can prevent theft and keep your products safe during transit.

Streamline Operations With an Integrated Weighing System

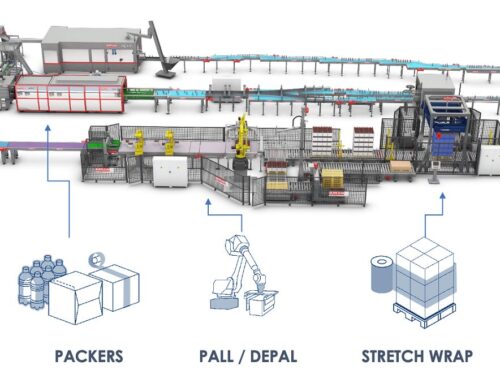

A weighing system that is integrated into the stretch wrap stage of your packaging line can have a significant impact on your ROI. By eliminating the need to double-handle the load, you can improve labor costs, freeing up valuable floor space and reducing your overall footprint.

In addition, the ability to weigh the load under the stretch wrapper’s turntable means that you can quickly recoup the cost of the system in shipping cost savings. As a result, an integrated weighing system is an essential tool for streamlining your operations.

Weighing your pallets is an important task that can help you save money on shipping costs, monitor theft, and streamline your operations. By choosing a semi-automatic stretch-wrapping machine with an integrated weighing system, you can make it easier and faster to get an accurate reading of how much each pallet weighs. This will help you avoid any costly mistakes and stay within your budget while shipping products.

Are you looking for a way to weigh your pallets easily and efficiently? Contact our team at Robopac USA today to learn more about our industrial scales and how they can benefit your business.