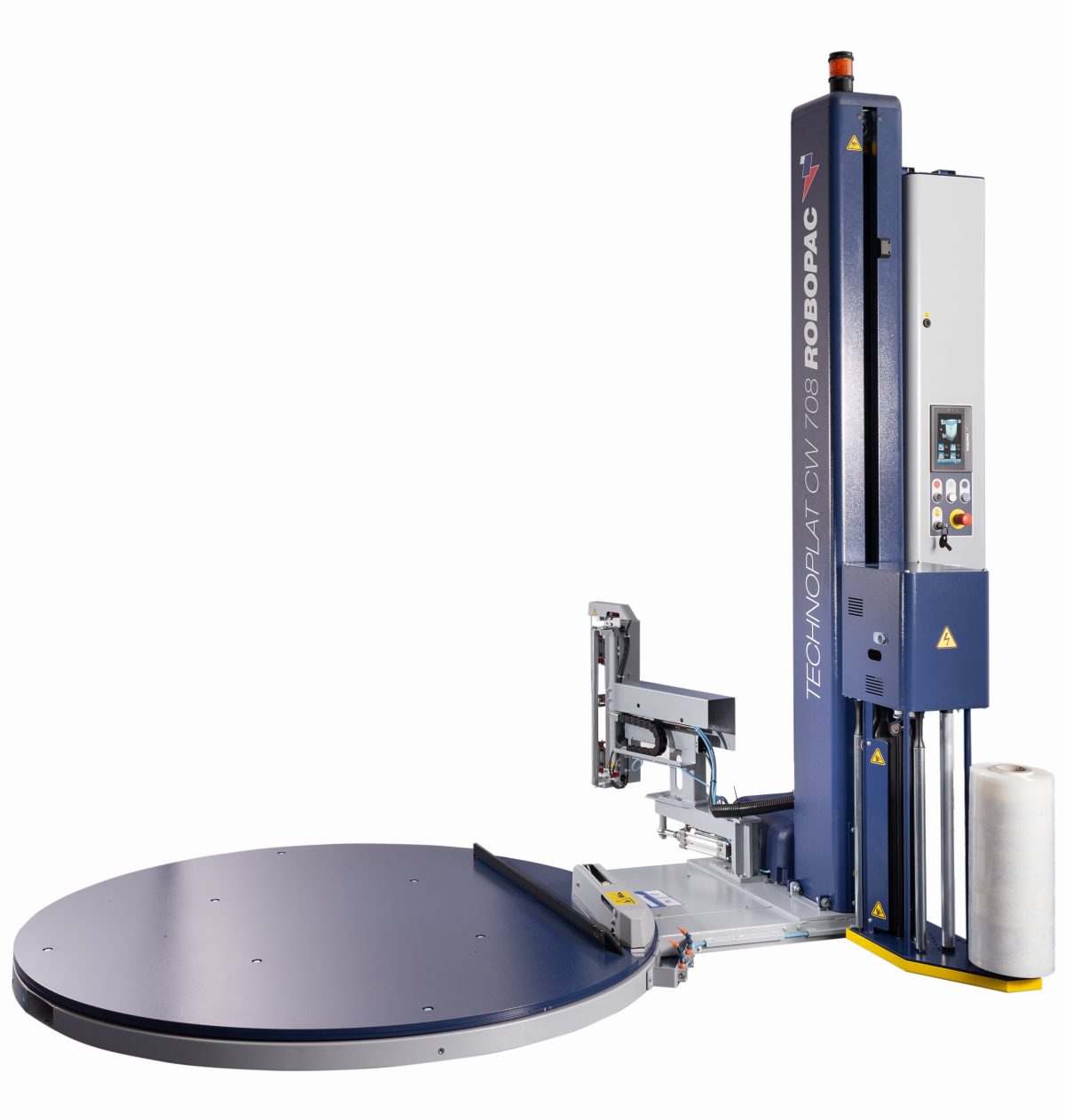

TECHNOPLAT 708 CS/CW Semi-Automatic Stretch Wrapper Machine

The Technoplat 708 CS (Clamp, cutting and sealing unit) or CW (cut and weld) semi-automatic stretch wrapping machine with turntable cuts and attaches the film tail to the load at the end of the wrap cycle for superior load containment.

The Technoplat 708 CS/CW semi-automatic shrink wrap machine saves 34 seconds of labor per load by keeping the operator on the fork truck. For the average customer, this translates to labor savings of $29,000 over 5 years and $60,000 over the life of the machine!

Our remote control start allows the fork truck operator to start the wrap cycle while staying on the fork truck. This allows them to leave the current load to pick up and stage another load which improves productivity.

R-Connect now included as standard feature (includes 36-month initial cellular data plan) with this semi-automatic stretch wrap machine

Our innovative CUBE Technology offered on this semi-automatic shrink wrap machine combines the following four (4) key factors to successfully wrap loads and ensure that they reach your customer in “as-made” condition by maintaining proper wrapping standards.

- Reduces film costs 30-55%

- Improves load containment

- Reduces product damage by 40%

REMOTE CONTROL

The remote control comes standard with the Technoplat and can control up to 4 units.

CLAMP, CUTTING AND SPREADING UNIT

The cut, clamp and spreading system (CS) ensures a perfect adherence of the final round of film on the wrapped product. The new aluminum clamp controlled by a pneumatic cylinder holds the film clearly and without slippage during cutting.

CLAMP, CUTTING AND WELDING UNIT

Ensure a perfect adherence of the film to the load for better containment with the cut, clamp and welding system (CW). The new aluminum clamp controlled by a pneumatic cylinder holds the film clearly and without slippage during cutting.

COLOR TOUCH SCREEN

The high performance 7-inch color touch screen with icons specifically designed and created by Robopac for our stretch wrap turntable machines has led to the implementation of the MULTILEVEL CONTROL function.

PVS CARRIAGE

Powered stretch system controlled by two motors. Stretch ratio adjustable from panel board from 150-400%. Force to the load controlled by patented electronic device and adjustable from panel board.

R-CONNECT EQUIPPED

R-Connect, standard for this turntable stretch wrapping machine, provides usage and performance data via the cloud, enabling you to meet Industry 4.0 demands by putting performance monitoring & optimization at your fingertips. Utilization drastically reduces downtime by giving you informational transparency, allowing you to connect with your machines remotely to investigate alarms, adjust parameters, & respond promptly. This Industry 4.0 innovation empowers you with actionable insight to continuously improve performance, cost savings, & automation.

Includes 36-month initial cellular data plan. Our Technoplat 708 CS for 110″ max load height includes R-Connect as a standard.