Automation is nothing new in the packaging industry. However, with the advent of new technologies, like Cube Technology and R-connect, and increasing customer demands, the industry has witnessed unprecedented transformation in recent years. In today’s competitive business world, it is no longer enough to package products manually. That’s why companies are investing heavily in automation to stay ahead of the game. Learn more about how automation is revolutionizing the packaging industry and how it can benefit businesses with this guide.

Improved Work Conditions

By integrating automation technologies in packaging facilities, companies can reduce worker fatigue and make the workplace less dangerous. By automating repetitive or physically strenuous tasks like wrapping or palletizing products, companies can reduce the risk of injury and create a safer, healthier workplace. Furthermore, automated technologies free workers up to carry out other tasks that require more creativity or flexibility. These tasks are often more satisfying or rewarding than physical, repetitive jobs, which leads to improved motivation and employee satisfaction throughout your business.

Reduced Costs

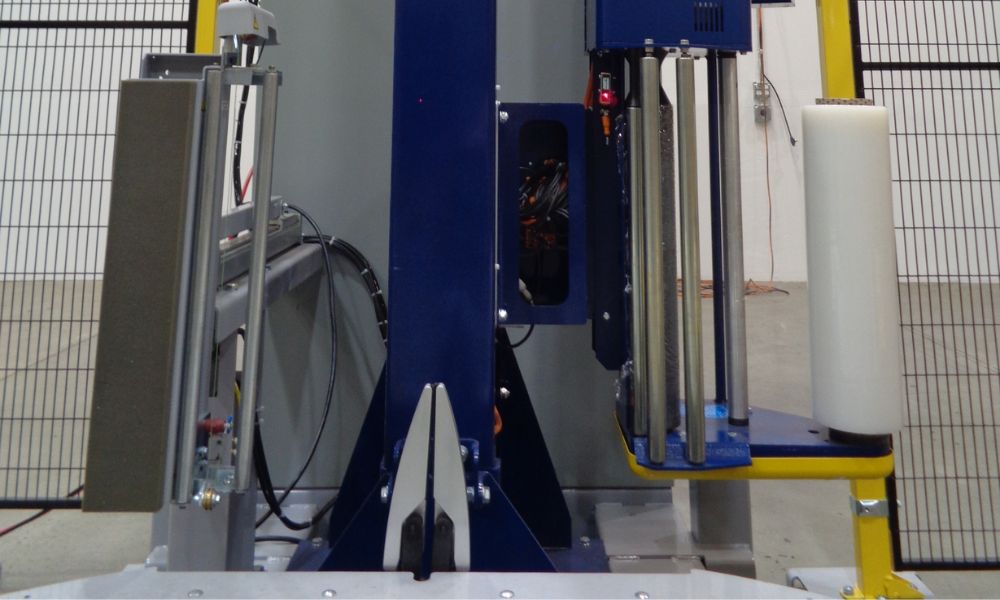

One of the most significant ways automation is revolutionizing the packaging industry is by reducing operating costs across the board. Automated systems can produce more products in a shorter period, increasing productivity to meet increased sales. Equipment like stretch wrappers and palletizers also reduce the need for man-hours, which translates into fewer expenses in terms of wages, insurance, and other employee benefits. Businesses that use automated processes can save money in the long run and reinvest capital savings in other areas of their business, like product marketing, research, and development.

Emphasizing Sustainability

Lastly, automation has opened doors for more sustainable packaging workflows. Automation in the packaging industry enables businesses to use materials more efficiently. For example, automatic and semi-automatic stretch wrappers offer more powerful pre-stretch for stretch film, which means businesses can use fewer materials without sacrificing quality or reliability.

Automated systems also help minimize product damage, reducing material and product loss and minimizing waste throughout the supply chain. As a result, companies that invest in automation can also reduce their environmental impact and boost their brand value to their customers.

Robopac USA helps companies find the packaging equipment they need to stay competitive and keep up with modern business demands. See why we stand out among stretch wrapper manufacturers when you explore our optimized secondary packaging solutions.