From enhancing product tracking to creating efficient designs, artificial intelligence (AI) is transforming the way the packaging industry operates. By harnessing the power of AI, companies can streamline their supply chains and create better experiences for both businesses and consumers. Explore how AI is revolutionizing the packaging industry.

Enhanced Product Tracking and Customer Visibility

AI technology significantly improves product tracking and customer visibility, resulting in a more seamless delivery experience. Robust tracking systems and AI-driven call centers and chatbots give customers detailed and accurate updates about their packages, including arrival time, current location, and transit status. With more precise tracking and improved customer engagement, AI contributes to a positive overall ordering and delivery experience that keeps customers coming back for more.

Furthermore, AI can detect possible tampering and theft by monitoring access to the packages, ensuring shipment security. Authorization-based tamper-proof packaging adds an extra layer of security, instilling trust and confidence in the customers as they wait for their products to arrive.

Data-Driven Packaging Optimization

One of the key ways AI is revolutionizing the packaging industry is through data-driven packaging optimization. By analyzing customer reviews, AI can identify weaknesses in packaging—such as wasteful packaging, hard-to-open designs, and product damage during transit—that often lead to dissatisfaction among users.

The algorithm can then help companies determine what packaging material is best for each product type and create smart designs to enhance both product protection and packaging sustainability. AI can also find ways to streamline packaging to use less materials, fit more products in each truckload, and improve sustainability across the supply chain.

Smart Packaging Protection

Another innovative aspect of AI in the packaging industry is the implementation of smart packaging solutions that use sensors to monitor environmental conditions such as temperature and humidity. This is particularly beneficial for temperature-controlled products and other goods that require specific conditions to maintain safety and quality through delivery.

By incorporating smart sensors in packaging, companies can effectively manage shipping temperatures and ensure goods stay secure throughout their transit. This extra layer of protection not only maintains product integrity but also helps decrease spoilage and waste, ultimately saving resources and costs for businesses.

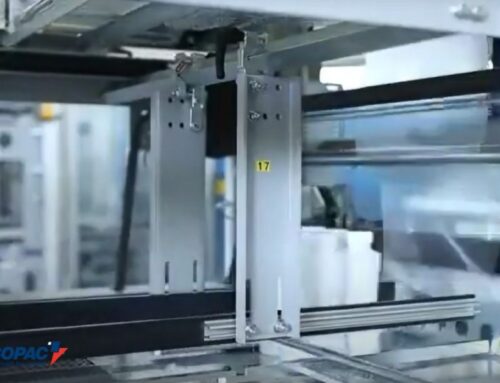

Are you looking for more ways to optimize your packaging workflow with cutting-edge technology? Robopac USA can help. With innovative secondary packaging solutions, such as our automatic palletizers, we help businesses streamline warehouse operations, improve sustainability, and build better supply chains.