There are several different secondary packaging solutions that can benefit your facility. To make the most of your packaging line, you must choose the equipment and processes that best fit your layout, workflow, workforce, and productivity needs.

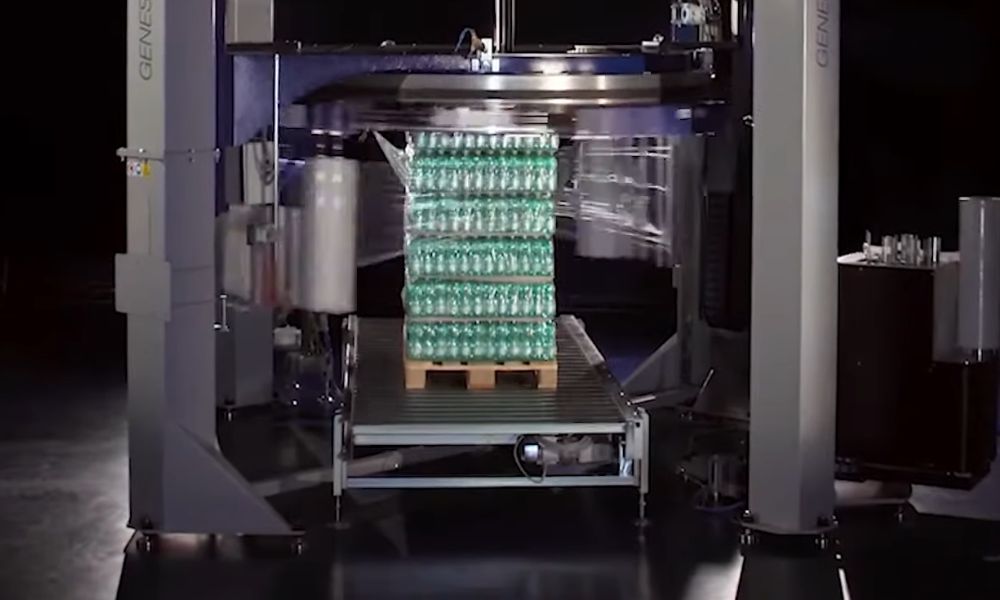

Automatic stretch wrappers offer the most powerful and efficient performance for your secondary packaging workflow. However, that doesn’t always mean they’re the most cost-effective or advantageous solution for your specific business. Learn more about when you should and shouldn’t use an automatic stretch wrapper with this rundown.

Productivity Requirements

One of the most important factors to consider before investing in automatic stretch wrapping equipment is the number of loads you wrap every day. The higher volume of product loads your facility sees, the more beneficial an automatic stretch wrapping solution will be.

If your productivity requirements are more than 35 loads per hour, the speed and efficiency of an automatic stretch wrapper will be worth it. Lower productivity requirements, on the other hand, might benefit more from a semi-automatic stretch wrapper.

You should also consider scalability when outlining your stretch wrapping solution. Are you planning on company growth in the near future? Is your current equipment able to keep up with an increase in productivity requirements? Make sure you choose the stretch wrapping solution that will benefit your business both now and in the years to come.

Worker Responsibility and Flexibility

Where are your employees most useful? An automatic stretch wrapper is the key to letting your workers focus on important tasks. Operators can stay on their fork trucks and continue to be productive even as pallets go through the wrap cycle.

Most semi-automatic stretch wrappers, on the other hand, require a worker to attach the film, monitor the load, and sometimes cut the film at the end of the process. This ties part of your workforce to your stretch wrapping equipment instead of enabling workers to focus on more important tasks. When you need to eliminate downtime on the floor and create more flexibility and efficiency in your workflow, automatic stretch wrappers are the way to go.

The Ability To Stage Loads

Efficiency is a crucial factor in deciding when you should and shouldn’t use an automatic stretch wrapper. Automatic stretch wrap machines empower better efficiency by allowing you to stage loads so that the conveyor can automatically take them into the wrap cycle. Workers can set the cycle and stage loads rather than manually starting the wrap cycle for every single load.

Deciding whether an automatic stretch wrapper is best for you comes down to your budget, capacity, and demand. When it’s time to choose the ideal secondary packaging solution for your facility, let the experts at Robopac USA help. We’ll work with you to implement the most effective equipment possible for your unique business needs.