Laser Guided Vehicles – LGV – Auriga PS

Auriga PS

Robopac USA introduces the Auriga Power Stacker for efficient, powerful, and dependable product transportation. Auriga PS is an automatic laser guided vehicle with covered forks. This compact forklift delivers agility and flexibility while still managing high-capacity product loads with ease.

In low position, the forks cover the rear wheels just like an electrical pallet truck. Thanks to the wheels’ position in relation to the load being carried, the PS model can move up to 3300 lbs. while being a machine of reduced dimensions. Auriga PS is therefore ideal to work in reduced space, between production lines for instance, or in warehouses as well.

Multiple power system options, such as Ethernet network compatibility, warehouse management system integration, and more, make the Auriga PS a versatile and effective forklift solution for your facility. Learn more about our laser-guided forklift systems and get your free quote today

PRODUCT BENEFITS

BATTERY REPLACEMENT OR CHARGING SYSTEMS

The battery replacement or charging system is designed to guarantee the wide autonomy for Auriga vehicles. There are three types: ad hoc charging, semi/automatic battery replacement or automatic battery replacement. Every vehicle has a charge indicator on-board managed by the microprocessor that liaises with the AGV Manager, keeping it constantly updated as to the status of the charge and consequently the need to refuel.

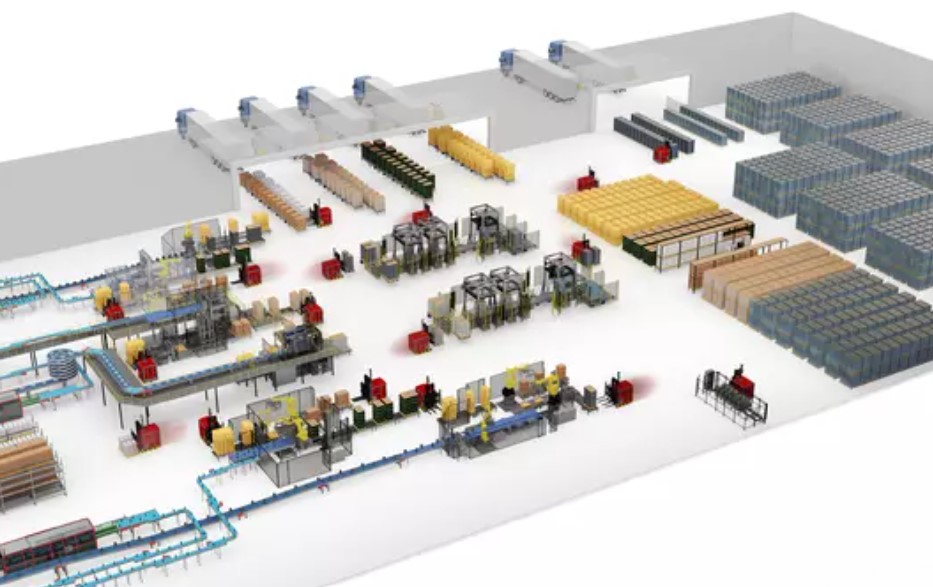

SUPERVISOR

The supervision system is designed to manage missions, criteria for the dynamic allocation of vehicles. It is interconnected with the other company devices, such as PC, PLC, database and ERP systems its purpose is to define, monitor, forecast and archive all the information relating to the logistics system devices, especially Auriga laser guided vehicles. Thanks to an entirely visual interface, an overall representation of the plant can be seen with the location of the vehicles and the related load. The status of every vehicle can be seen in order to check its operating parameters.

THE NETWORK

The Ethernet network used for the systems designed by OCME is designed by highly qualified specialized technicians, capable of guaranteeing perfect operation and maximum availability of the infrastructure. The network, which is part wired, and part wireless, is designed for the LGVs to liaise with the central traffic management system and concurrently assess the requests originating from the operators (via normal handheld devices), from palletizers/depalletizers or in general from any other plant, irrespective of the language and of the communication protocol used.

WAREHOUSE MANAGEMENT SYSTEM (WMS)

Integrated warehouse management is obtained thanks to algorithms which are capable of making the correct choices to exploit all the available space. The AGV Manager guides the vehicles on specific missions based on the load they need to load or unload according to various parameters.

| SPECIFICATIONS | AURIGA 15 PS | |

|---|---|---|

| Max unit Load Weight (lbs.) | 3300 | |

| LGV Height* (inches) | 118 | |

| Lifting height* (inches) | 118 | |

| Max Height Lift Mast (inches) | 142 | |

| Fork length* (inches) | 47 | |

| LGV Length (inches) | 87 | |

| LGV Width* (inches) | 32 | |

| Wheel base (inches) | 46 | |

| Max. speed (inches/s) | 67 | |

| Max speed Fork Lift (inches/s) | 6 | |

| LGV weight with battery (lbs.) |

3968 | |

| *Customizable | ||